Ah, cleanroom gloves – those seemingly mundane yet utterly essential guardians of sterile spaces. They’re the unsung heroes in industries where a stray particle can spell disaster, where contamination is not just a nuisance, but a potential showstopper.

Cleanroom Gloves: What’s the Big Deal?

You might be thinking, “Gloves are gloves, right? What makes these so special?”. Well, hold onto your beakers, folks, because the world of cleanroom gloves is far more fascinating (and important) than meets the eye. We’re not talking about your average pair for gardening here!

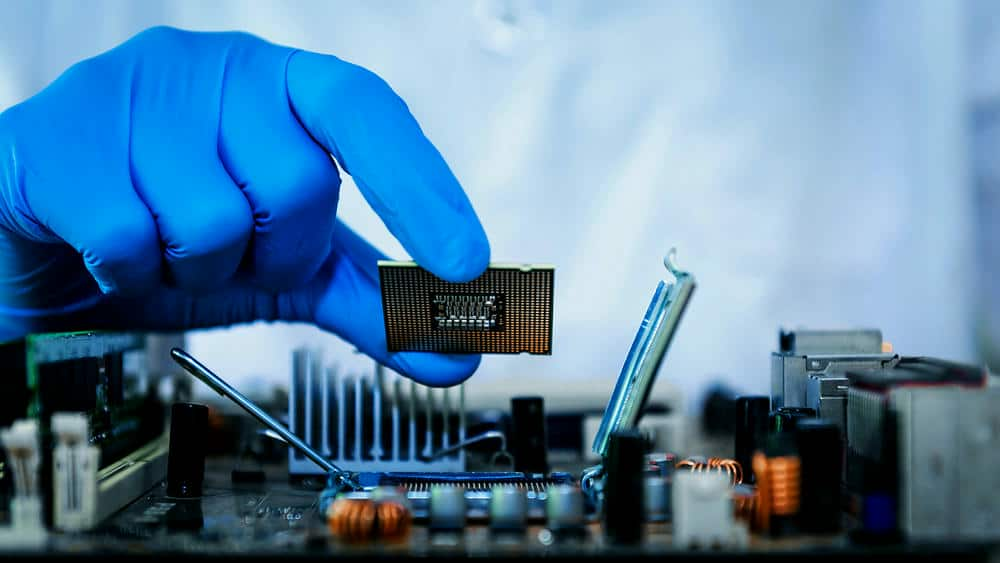

Cleanroom gloves are specifically engineered to prevent contamination in environments demanding the utmost cleanliness. Think of them as the first line of defense against microscopic intruders.

Why are Cleanroom Gloves Crucial?

Let’s cut to the chase. Why all the fuss about pristine gloves?

Imagine this: you’re painstakingly assembling a delicate electronic component, or perhaps researching cutting-edge pharmaceuticals. A stray speck of dust, a bead of sweat, or a rogue oil molecule from your hand could compromise the entire operation! 😨

Cleanroom gloves act as a barrier, protecting:

- Products: Shielding sensitive materials and products from human-generated contamination.

- Processes: Maintaining the integrity of research, manufacturing, and other sensitive processes.

- People: Safeguarding personnel from exposure to hazardous substances often handled in cleanrooms.

But it’s not just about being “clean.” Cleanroom gloves must meet stringent industry standards, offering specific properties like electrostatic discharge protection, chemical resistance, and even compatibility with certain cleaning agents.

Types of Cleanroom Gloves: A Material World

Just like there’s no one-size-fits-all solution to life’s problems, there’s a whole wardrobe of cleanroom gloves, each tailored to specific needs. Let’s delve into the most common materials:

1. Latex Cleanroom Gloves

Ah, latex, the OG of cleanroom hand-wear! These gloves, derived from natural rubber, boast exceptional elasticity and dexterity, making them a favorite for tasks demanding fine motor control.

Pros:

- Superb sensitivity and flexibility

- Biodegradable, making them a more eco-friendly choice compared to some synthetics.

Cons:

- Potential for latex allergies 😩, which are unfortunately quite common

- Limited chemical resistance

2. Nitrile Cleanroom Gloves

Next up, we have nitrile gloves, the synthetic superheroes of the cleanroom! They’re known for their impressive resistance to punctures, tears, and a broader range of chemicals compared to their latex counterparts.

Pros:

- Highly puncture-resistant and durable

- Latex-free, hurrah for those with allergies!

- Wider chemical compatibility

Cons:

- Not quite as elastic or form-fitting as latex

- Can be slightly less sensitive to touch

3. Vinyl Cleanroom Gloves

On a budget? Vinyl gloves swoop in as the economical choice for general cleanroom tasks where durability isn’t the top priority.

Pros:

- Cost-effective

- Suitable for short-duration tasks and frequent glove changes

Cons:

- Less tear-resistant than nitrile or latex

- Not ideal for handling harsh chemicals

4. Neoprene Cleanroom Gloves

Need to battle potent chemicals and maintain a grip on slippery surfaces? Neoprene gloves are here to save the day! They’re renowned for their resistance to a broad spectrum of chemicals, oils, and even flames. 🔥

Pros:

- Superior chemical and heat resistance

- Excellent grip, even in wet conditions

Cons:

- Can be less flexible than other materials

- Not suitable for individuals with neoprene allergies

5. Polyisoprene Cleanroom Gloves

Polyisoprene, a synthetic version of latex, is gaining popularity in the cleanroom scene. They offer a similar feel and dexterity to natural latex but without the pesky allergy concerns.

Pros:

- Similar properties to latex without the allergy risks

- Excellent tactile sensitivity

Cons:

- Less puncture-resistant than nitrile

- May be pricier than some other options

Choosing the Right Gloves for Your Cleanroom Needs

Navigating the world of cleanroom gloves might feel overwhelming. Here’s a handy-dandy table to help you choose the best option for your specific needs:

| Glove Material | Pros | Cons | Best Applications |

|---|---|---|---|

| Latex | Elastic, Dexterous, Eco-Friendly | Latex Allergy Risk, Limited Chemical Resistance | Medical Device Assembly, Laboratories, Pharmaceutical Manufacturing |

| Nitrile | Durable, Puncture-Resistant, Chemical Resistant | Not as Elastic as Latex, Slightly Less Sensitive | Pharmaceutical Manufacturing, Chemical Handling, Electronic Assembly |

| Vinyl | Economical | Less Durable, Not Ideal for Harsh Chemicals | Food Handling, General Cleanroom Tasks |

| Neoprene | Excellent Chemical and Heat Resistance, Superior Grip | Less Flexible, Not Suitable for All Users | Automotive Manufacturing, Aerospace, Handling Solvents |

| Polyisoprene | Latex-like Properties, Hypoallergenic | Less Puncture-Resistant than Nitrile | Medical Device Assembly, Laboratories |

Remember, selecting the appropriate cleanroom gloves depends on various factors, including the:

- Nature of your work

- Sensitivity of your products or processes

- Potential hazards (chemicals, heat, etc.)

- Budget constraints

Deciphering Cleanroom Glove Classifications

Hold on tight, because we’re about to get technical! Cleanroom gloves are rigorously classified based on their particle and extractable content. Let’s decode the jargon:

1. Particle Count: How Clean is Clean?

Ever wondered how many microscopic dust bunnies could be hiding on a glove? Cleanrooms have strict limits, and particle count testing is serious business. This process determines the number of particles of specific sizes present on the glove’s surface.

Gloves are often categorized as:

- Class 100/ISO 5: Ultra-clean, for the most critical environments.

- Class 1000/ISO 6: Clean, but with a slightly higher particle allowance.

- Class 10,000/ISO 7: Suitable for less sensitive cleanroom applications.

2. Extractables: Keeping Things Pure

Extractables refer to the substances that can leach out of the glove material, potentially contaminating whatever they touch.

These could include:

- Ions

- Residues (chemicals, lubricants, etc.)

- Other impurities

Testing ensures these extractable levels are within acceptable limits.

Cleanroom Glove Standards: The Nitty-Gritty

Cleanrooms don’t mess around when it comes to standards. Here are the major players in the glove game:

1. ASTM International

This powerhouse organization develops voluntary consensus standards for materials, products, systems, and services. Key standards related to cleanroom gloves include those for:

- Particle levels (ASTM D4806): Evaluating particle contamination

- Extractables (ASTM D6319): Measuring ion and other residue levels

2. International Organization for Standardization (ISO)

Ah, ISO, known for its globally recognized standards. Relevant standards for cleanroom environments and gloves include:

- ISO 14644: Establishes guidelines for classifying and controlling airborne particles in cleanrooms.

- ISO 9001: Sets quality management system requirements, crucial for cleanroom glove manufacturers.

Donning (and Doffing) Cleanroom Gloves Like a Pro

Wearing cleanroom gloves isn’t as simple as slipping on a pair of mittens. Proper donning and doffing (that’s fancy talk for putting on and taking off) techniques are critical for maintaining sterility.

The Art of Donning

- Scrub-a-Dub-Dub: Thorough handwashing is non-negotiable! Use a specialized cleanroom soap and water system, and don’t forget those fingernails!

- Dry Time: Completely dry your hands with a cleanroom-approved, lint-free wipe or air dryer.

- Glove Up!: Carefully remove the gloves from their packaging, avoiding any contact with non-sterile surfaces.

- Double Glove It!: In ultra-sensitive environments, double gloving is often required. The outer glove acts as a sacrificial layer.

The Doffing Dance: Preventing Cross-Contamination

Removing gloves without spreading those microscopic troublemakers requires finesse:

- Outer Layer First: Pinch the cuff of one glove, careful not to touch your skin, and peel it downwards, turning it inside out.

- The Great Escape: With the first glove off, slip two fingers of your ungloved hand under the cuff of the remaining glove, again avoiding skin contact. Peel it off, turning it inside out to contain any potential contamination.

- Disposal Duty: Dispose of the gloves in a designated cleanroom waste container.

The Future of Cleanroom Gloves: Innovation on the Horizon

Just like everything else, the world of cleanroom gloves is constantly evolving. Keep an eye out for exciting advancements like:

- Smart Gloves: Imagine gloves embedded with sensors that monitor contamination levels or provide real-time feedback on hand hygiene. The future is near!

- Sustainable Solutions: The push for eco-friendly practices is driving research into biodegradable and more sustainable glove materials.

- Enhanced Comfort and Dexterity: Manufacturers are continually improving glove designs to enhance comfort, flexibility, and tactile sensitivity, making it easier for users to perform delicate tasks.

Cleanroom Gloves: FAQs

1. What are cleanroom gloves made of?

Cleanroom gloves are commonly made from materials like latex, nitrile, vinyl, neoprene, and polyisoprene, each with unique properties to suit different cleanroom needs.

2. How often should you change cleanroom gloves?

The frequency of glove changes depends on factors like the cleanroom’s classification, the tasks being performed, and the risk of contamination. In general, it’s recommended to change gloves frequently, especially after handling potentially contaminating materials or if any damage is observed.

3. Can you reuse cleanroom gloves?

No, reusing cleanroom gloves is a big no-no! 🙅♀️ Once a glove has been worn, it can harbor particles, microorganisms, and other contaminants. To ensure a sterile environment, use a fresh pair every time.

4. Where can I buy cleanroom gloves?

Cleanroom gloves are readily available from various suppliers specializing in scientific, industrial, and cleanroom products. Look for reputable online retailers or distributors catering to these industries.

5. Can you wash cleanroom gloves?

While it might be tempting to try to extend the life of your gloves, most cleanroom gloves are not designed to be washed or reused. Washing can compromise the material’s integrity, reducing its effectiveness as a barrier against contamination.

6. Why do some cleanroom gloves have textured fingertips?

Gloves with textured fingertips are designed to enhance grip, especially in situations involving wet or slippery objects. The tiny ridges or patterns on the surface create friction, providing a more secure hold.

Conclusion: The Importance of Choosing Wisely

As you venture into the realm of cleanrooms and their meticulous protocols, remember this: cleanroom gloves aren’t just an accessory—they’re essential tools in upholding sterile environments, protecting both people and sensitive products or processes. Choosing the correct gloves based on material, classification, and industry standards is paramount. So, go forth and glove up with confidence! Your meticulous approach ensures that your cleanroom remains a sanctuary of precision and purity.

MedicW is committed to being your trusted partner in providing high-quality medical consumables. Explore our comprehensive range of products and discover how we can support your healthcare needs. Visit us at medicw.com or contact our team at [email protected].

Link to this article: Navigating the World of Cleanroom Gloves